Do You Want To Make Compost Quickly?

Long time ago, if you want make compost from organic wastes, most people would find a place to piled organic materials and let them stand for a year to get compost for use. Or just dig a hole and put down the raw materials. In today’s view, these seems like the ancient composting method to reuse the organic wastes. But, with the increasing awareness of environmental protection, these organic wastes such as animal manure, green waste are often used to produce organic fertilizers. Thus, these inefficient composting methods are not suitable for large scale compost production. In ShunXin, we have rapid composting machine to deal with organic fertilizer raw material.

As a professional fertilizer equipment manufacturer for more than 30 years, ShunXinhas high efficient rapid composting machine for sale to make compost quickly. Do you want to know how does our equipment can speed up the composting process?

What Kinds Of External Factors Would Affect The Composting Process?

- Moisture Content. In general, the optimal moisture content of compost materials should be maintained at 60%. If the moisture content of the raw material is low, it should be adjusted to add more water. Otherwise, the composting process will be very slow and need a long time for the fermentation work. If the moisture content is too high, it will affect the process of aerobic fermentation and produce lots of unpleasant odor. So, it is necessary to control the moisture of raw materials before composting work.

- Particle size – The smaller the raw material size, the more surface area you’re providing for the microorganisms to do their work. This is particularly important when composting in smaller scale, as smaller particles speed up the composting process. Aim for shredded pieces no more than one inch in width. So, it is necessary to equip a compost crusher machine to speed up the composting process. It will short the fermentation time greatly.

- Air – Oxygen is very important to the microorganisms that help break down compost materials. Frequent aeration is key when organic waste composting. With the help of ShunXincompost turning facility, you do not need to care about the ventilation of your compost piles.

Types of rapid composter machine

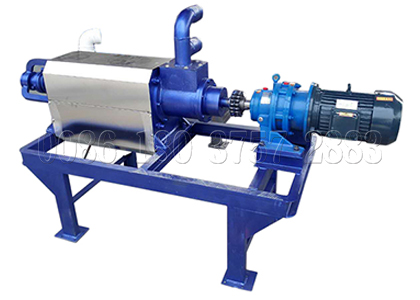

In our compost machinery factory, we have different types of rapid composting machines. And every rapid composter machine has its own special function. We will introduce you two kinds of rapid compost fertilizer making machine.

The first one is in vessel composting machine. As the fermentation tank with advanced technology, it has the character of high degree of automation. In addition, in the whole compost fertilizer fermentation process, you can’t smell a stench. You only need one or two workers to control this machine. Most importantly, you just have to wait 7-10 days, and then you can get the fermented fertilizer.

The second one is rapid windrow composting machine. Crawler type composting machine is a typical windrow compost production equipment. For getting compost fertilizer, the material needs to be piled up into stack. Then the material is stirred and crushed at regular intervals by the rapid turning machine. By using this kind of rapid composter machine, you need to spend 20-30 days.

How Do You Speed Up The Composting Process-Five Factors You Can Control For Fast Composting

- Size it right. Compost piles should not be too big or too small. If it is too big, it will make difficult for oxygen to seep into the inside part of compost pile before it is exhausted. As a result, it will cause anaerobic area and produce unpleasant odor. Suitable size of compost piles can provide a better composting environment for organic decomposition. In general, the most suitable size for composting is about 1 cubic yard (3 ft square by 3 ft high).

- Turn it over. Composting is a process that organic matter has been decomposed. In this process, microbes need oxygen to do their work and keep their activities. If you a composting without turning it over, it will become a process of anaerobic compost and produces ammonia, hydrogen sulfide, methane and other organic acids. More terrible thing is most of these producers are smell badly.

- Optimize compost material. A good compost product can not do without good organic ingredients. If the organic nutrients in the compost materials are not enough, we can add additives to the compost materials and create a good living, breeding and working environment for microorganisms.

- Keep it moist but not be soggy. Composting works best if the moisture content of materials in the pile is about 50 percent. Too much moisture in compost material will leading slow and smell decomposition. Too dry will cause slow decomposition or will not occur at all.

- Shred the compost materials. It is one secret to making fast compost. Because this way increased the surface area microbes have to work and improved their working efficiency.

Advantages of Rapid Composting System

- Rapid composting system shortens the time of organic fertilizer production. And it will save your investment in your plant.

- The rapid composting technology replace the shortfall of traditional composting method. In a sense, it let the development compost technology enter a new stage.

- The rapid composting machine keep higher nutrient content in products due to less leaching of nutrients.

After-Sale Service From ShunXinCompost Machinery

- In the world, we have more than 100 service engineers. And we have the faith to do 24 hours of uninterrupted time to provide you with “15 minutes of quick response, 24 hours completed” service.

- We have a perfect sale service, it can solve your questions about our equipment and our company.

- A large number of professional reserves. We promise that the spare parts will be delivered to you within 72 hours.